Since 1958, architects and designers have specified photo metal for high-value outdoor and indoor signage projects such as wayfinding signs, blueprint reproductions, building certification plaques and donor recognition plates.

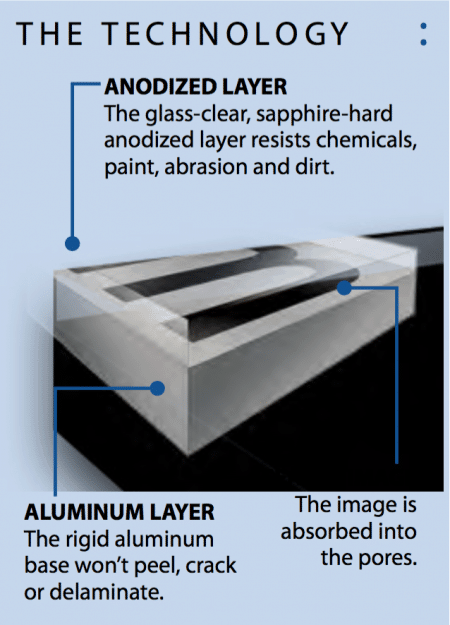

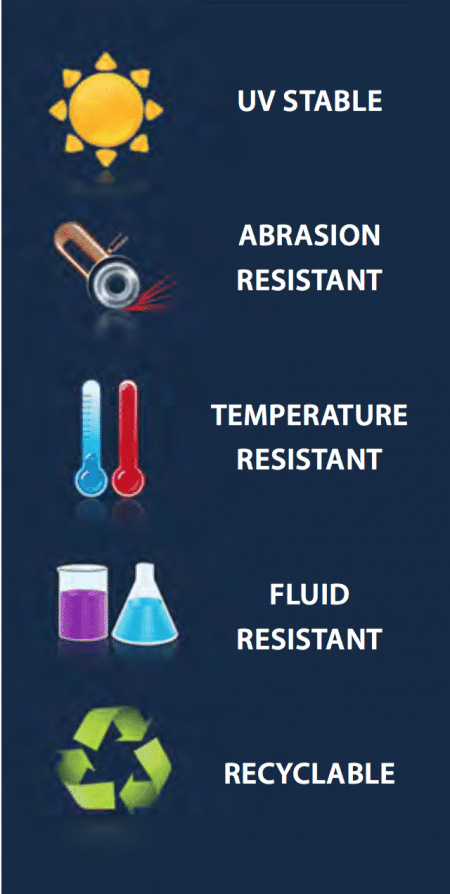

Photo metal photosensitive anodized aluminum allows you to capture rich, photographic quality images inside of metal – providing unmatched longevity and the durable, modern look of anodized aluminum. Because photo metal is a photographic process, its image resolution, clarity and durability are superior to printed or etched signs. The photo metal image is cleanable, graffiti proof and impervious to sunlight and abrasion.

Photo metal is designed for permanency – it will not fade or need to be replaced. If replacement is desired, photo metal is 100% recyclable.

Customized photo metal components can be made to your specifications.

Because of its ability to perform across a range of challenging environments, photo metal meets an array of government, industrial and military specifications.

| Characteristic | Result |

|---|---|

| Abrasion Resistance | No pronounced image loss, degradation or reduced readability after 7,000 cycles on an abrading wheel. |

| Acid Corrosion | No deterioration or image degradation after 24 hours in 3% nitric acid. |

| Heat Resistance | No legibility loss or degradation when subjected to 1,000°F. |

| Salt Spray Corrosion | No deleterious effect after 720-hr salt spray (fog) test. 2,6 “Very Good” corrosion resistance after 113 days seawater exposure. |

| Accelerated Light and Weather Resistance | No pronounced deterioration of legibility after 400-hr carbon arc weatherometer exposure. ( ≈ 20+ year outdoor life) |

| Accelerated Oxygen Aging | No discoloration or fading after 96-hr/300 psi/ 70°C oxygen bomb aging |

| Stain Resistance | No black fading when plates are exposed to tincture of iodine. |

| Cleaning Resistance | No deleterious effects when tested with alkaline cleaners (MILC-87937 or equivalent) for aircraft surfaces. |

| Low Temperature Resistance | No deleterious effect or image fade after 1 hour at -50°F. No impairment of legibility upon exposure at -67°F. |

| Organic Solvent Resistance | No softening, staining or noticeable fade after 24-hr exposure to: JP-4 fuel, Gasoline, Mineral Spirits, Methyl Ethyl Ketone, Turpentine, Turbine & Jet Fuel, Kerosene, Xylol, Acetone, Toluol, Heptane, Trichlorethylene, MIL-H-5606 Hydraulic Fluid and MIL-L-7808 Jet Engine Oil. |

| Fungus Resistance | Visual reading of “0” per ASTM-G21. |

| Thermal Shock | No deterioration after 3 cycles between -65°C and 125°C |

| Moisture Resistance | No deterioration after 10 humidity cycles per MIL-STD-202, method 106. |

Material: Anodized Aluminum Sheets

Sizes: 10”x 12”, 12”x 20”, 20”x 24”, 20”x 40”, 24”x 40”

Thicknesses: .003”, .005”, .008”, .012”, .020”, .032”, .039”, .063”, .090”, .125″

non-reflective with dull finish

semi-gloss medium reflective material

brushed to resemble a stainless steel finish

highly reflective, mirror like

To order give us a call at (800) 833-8397 or email us today!